Drop ship swag & event merchandise

Send your swag anywhere in the world with a few clicks.

Drop ship swag & event merchandise

Drop ship swag & event merchandise

Send your swag anywhere in the world with a few clicks.

Send your swag anywhere in the world with a few clicks.

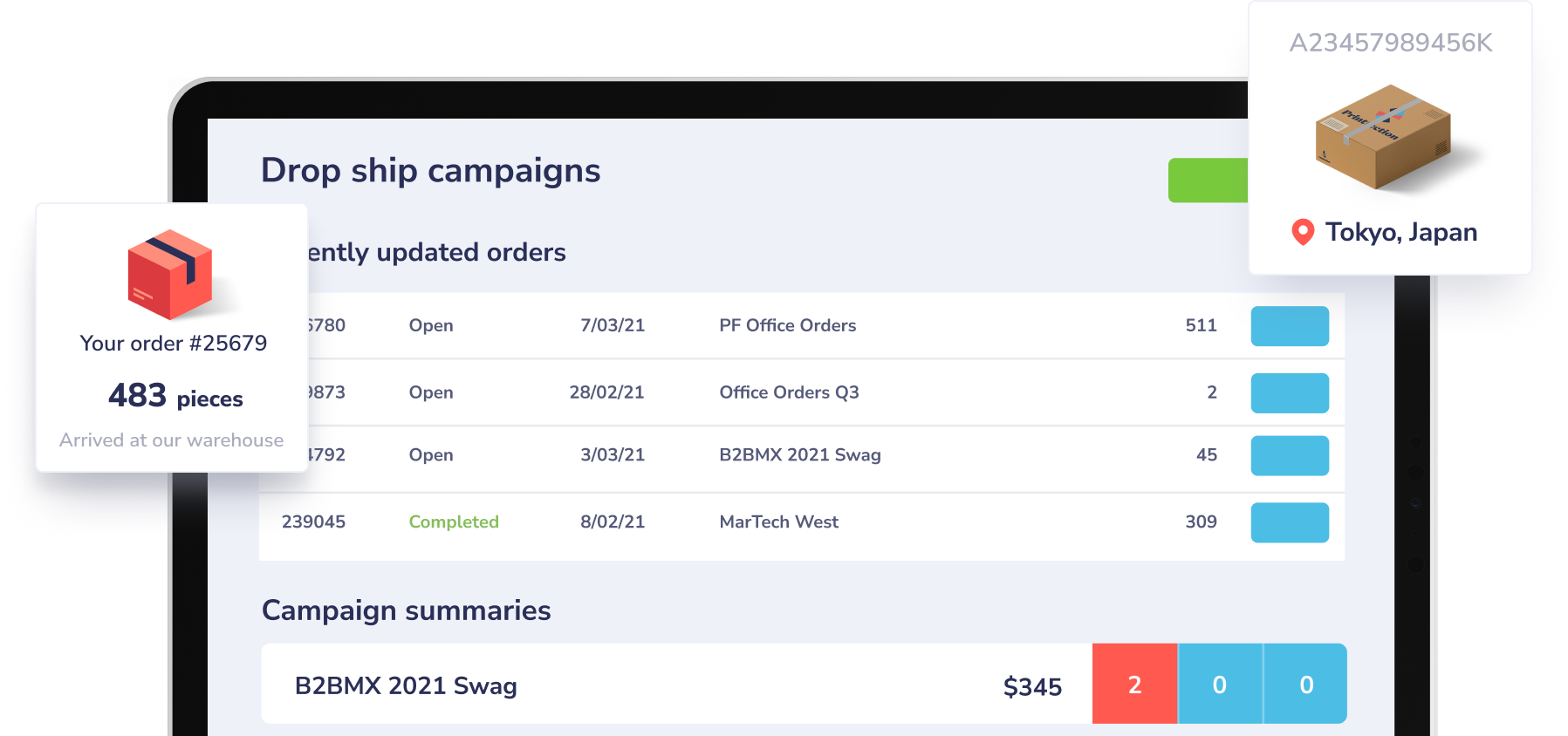

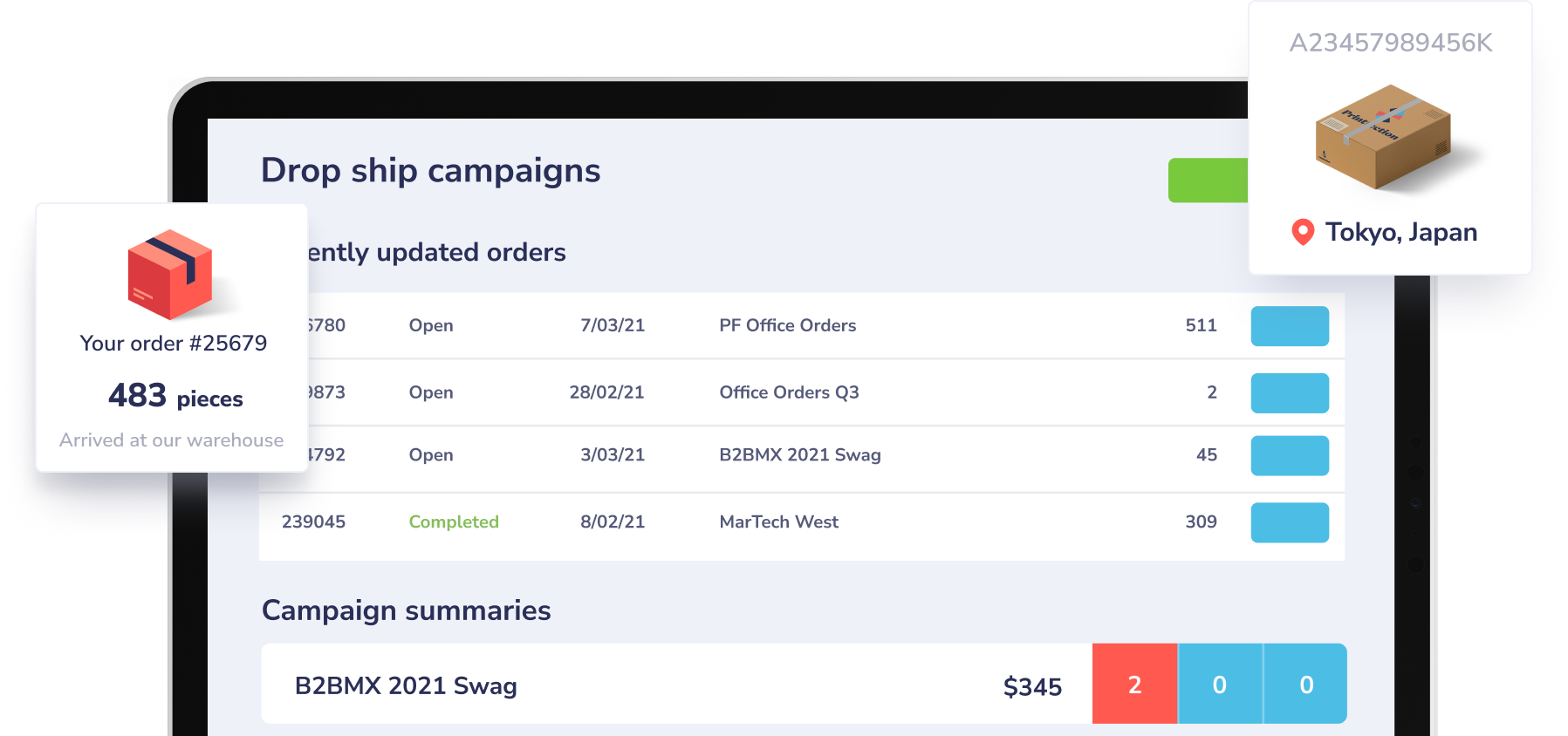

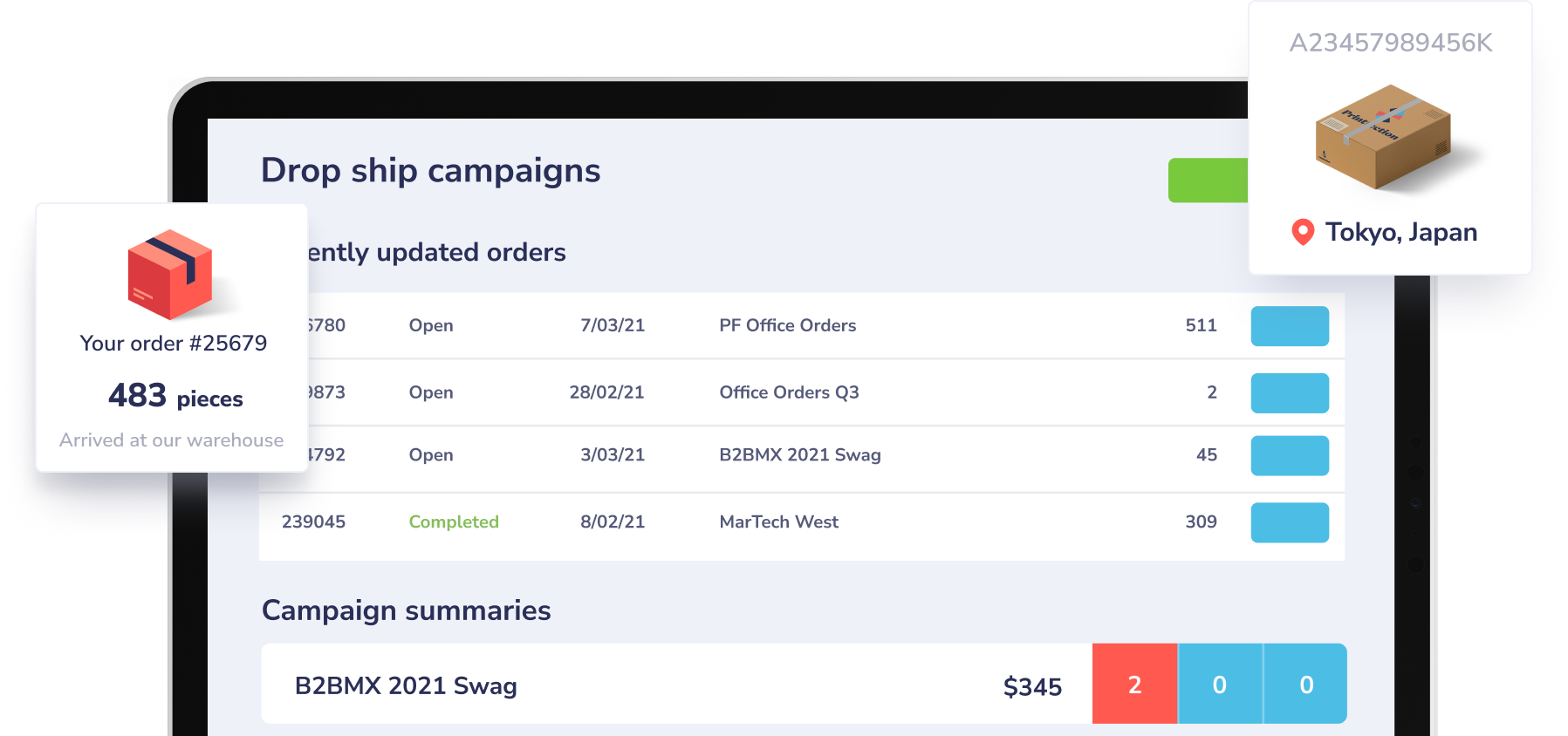

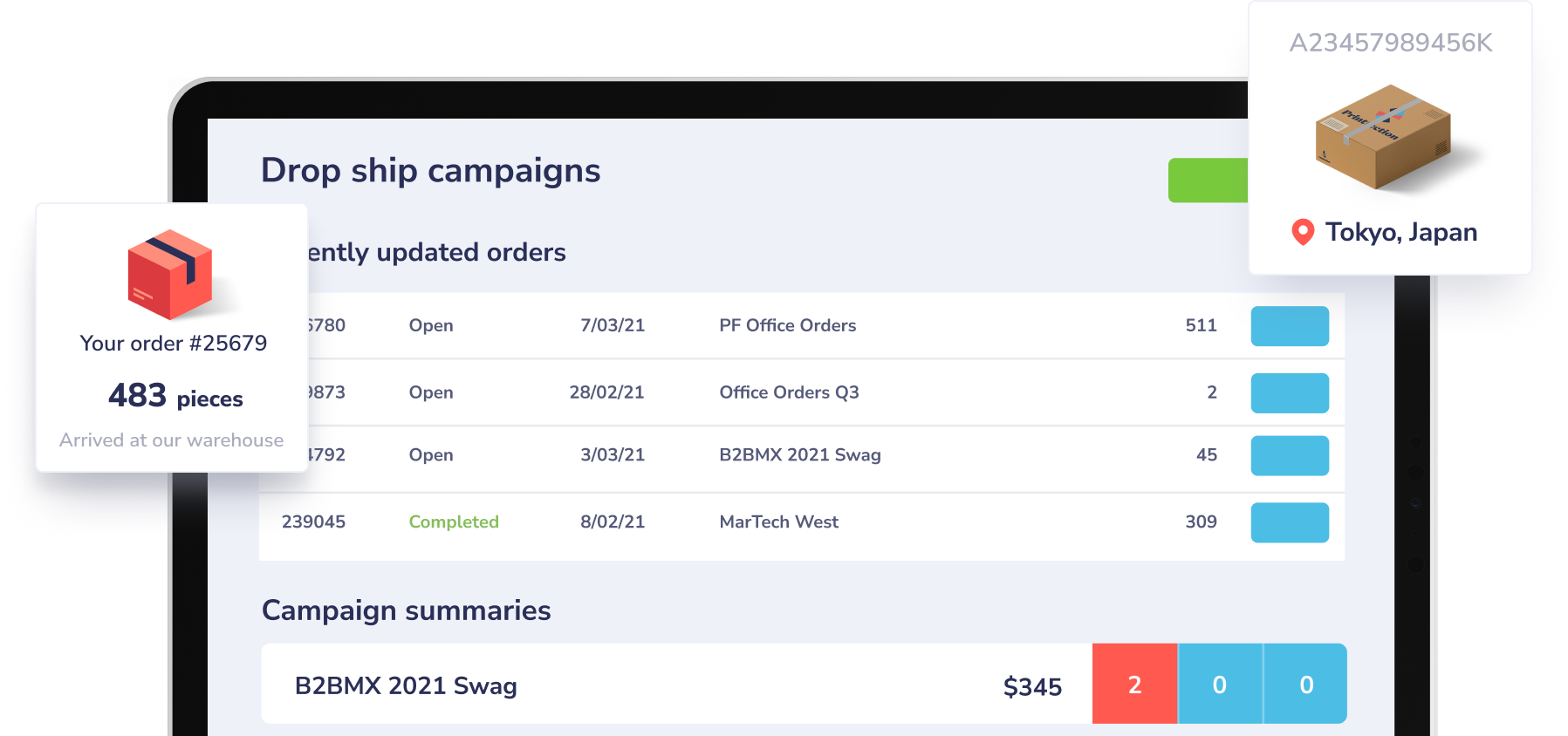

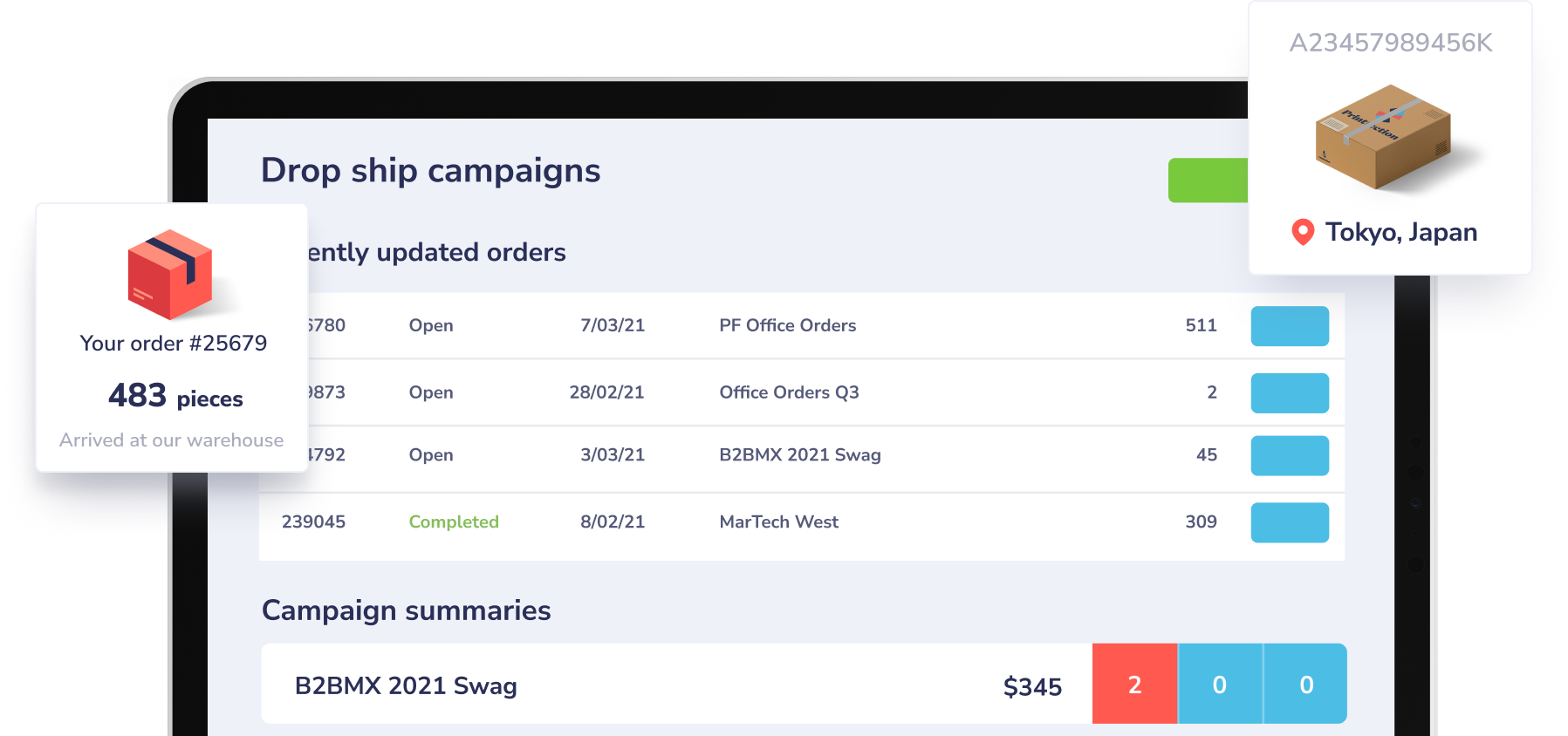

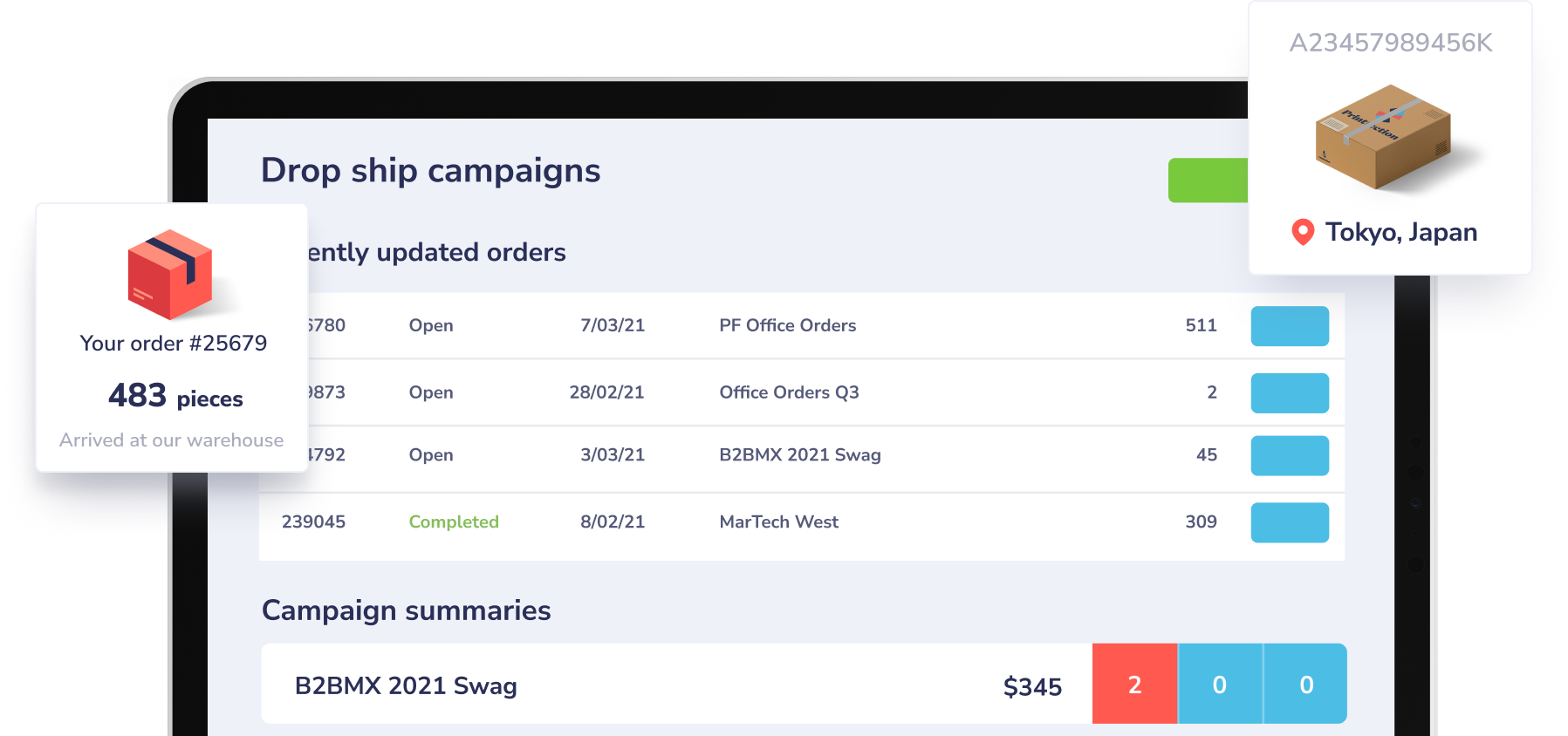

Drop ship to your events like a boss

Use Printfection to easily create & order swag online and then drop ship to your office or event venue.

We deliver internationally and we can roll t-shirts by size for events.

Drop ship to your events like a boss

Use Printfection to easily create & order swag online and then drop ship to your office or event venue.

We deliver internationally and we can roll t-shirts by size for events.

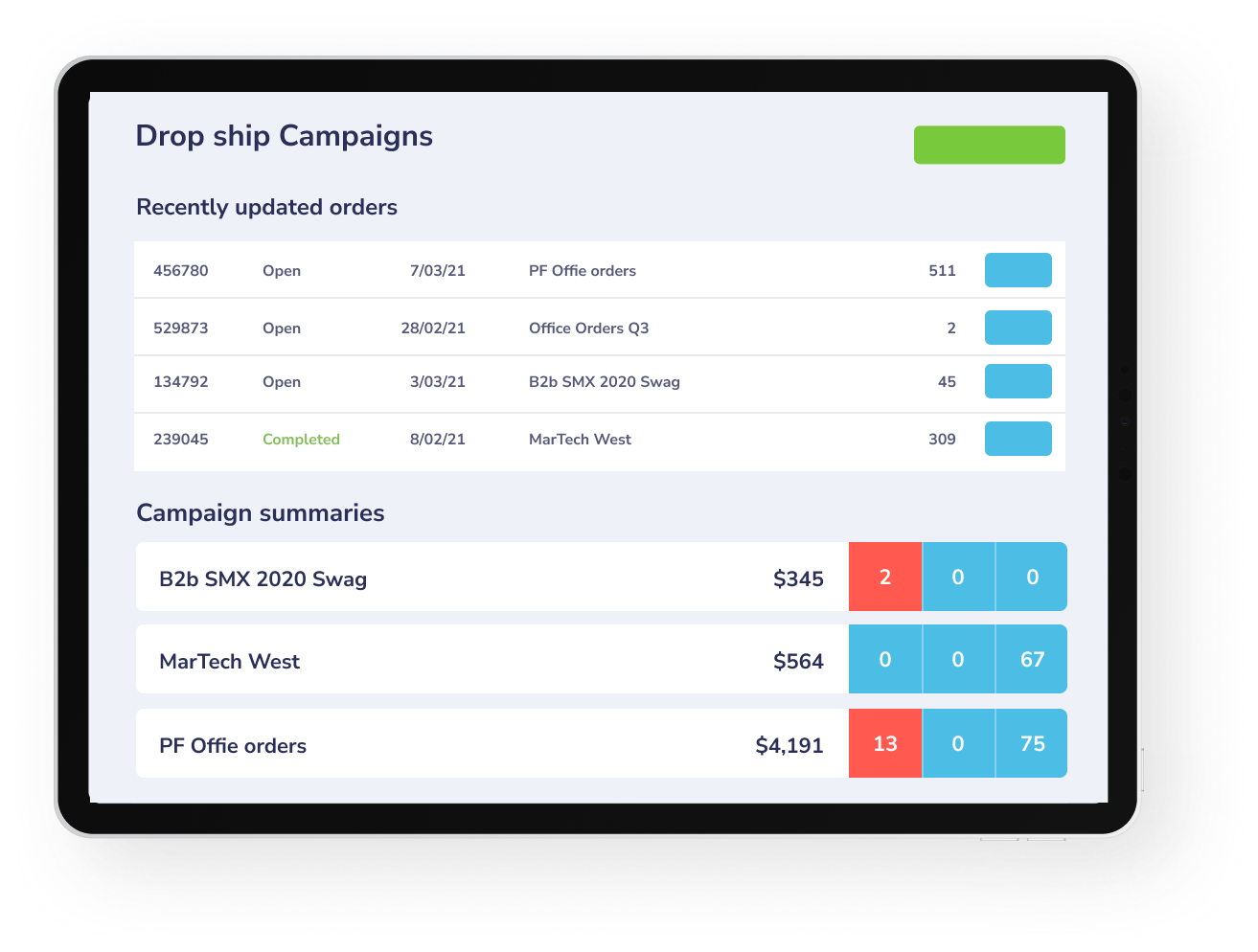

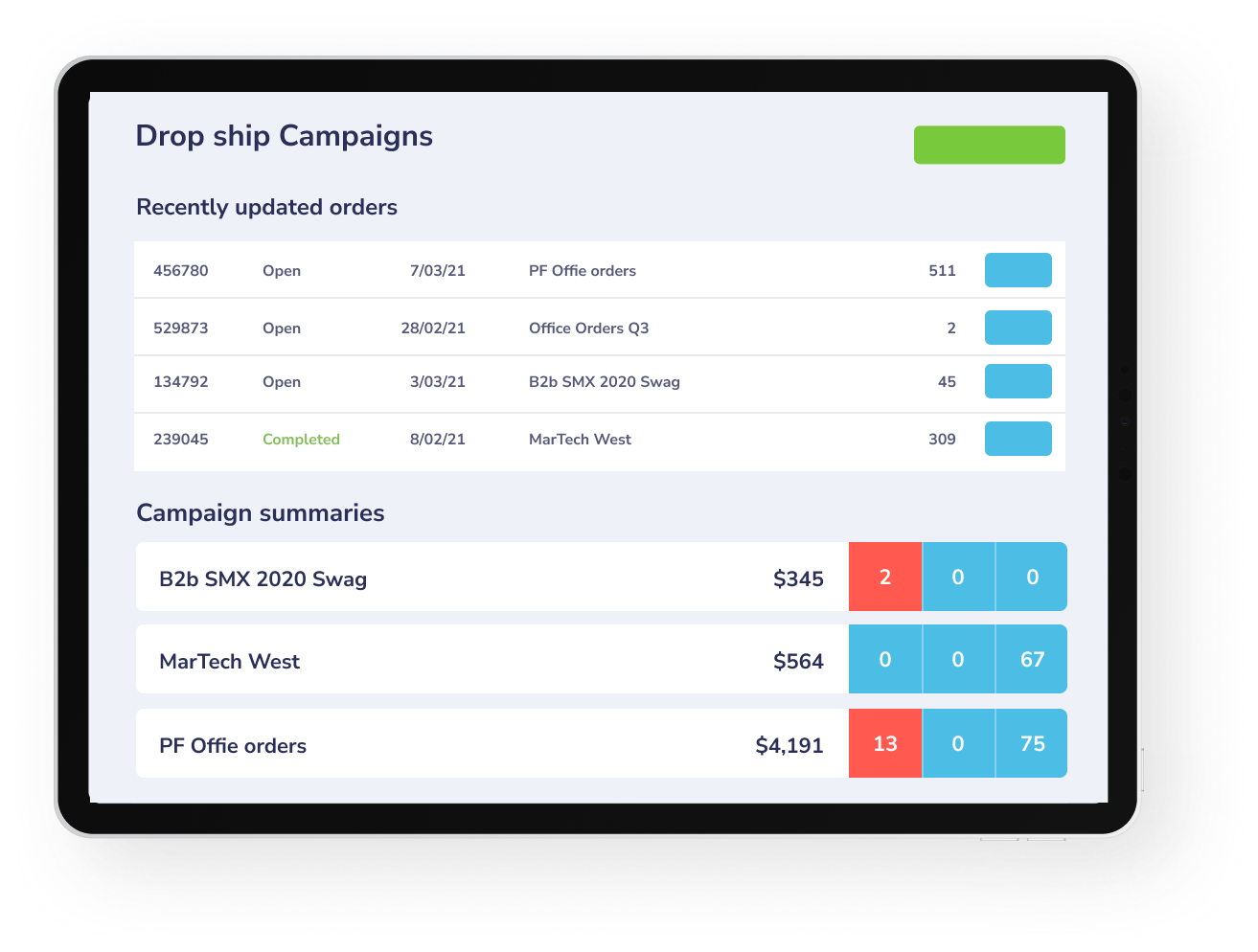

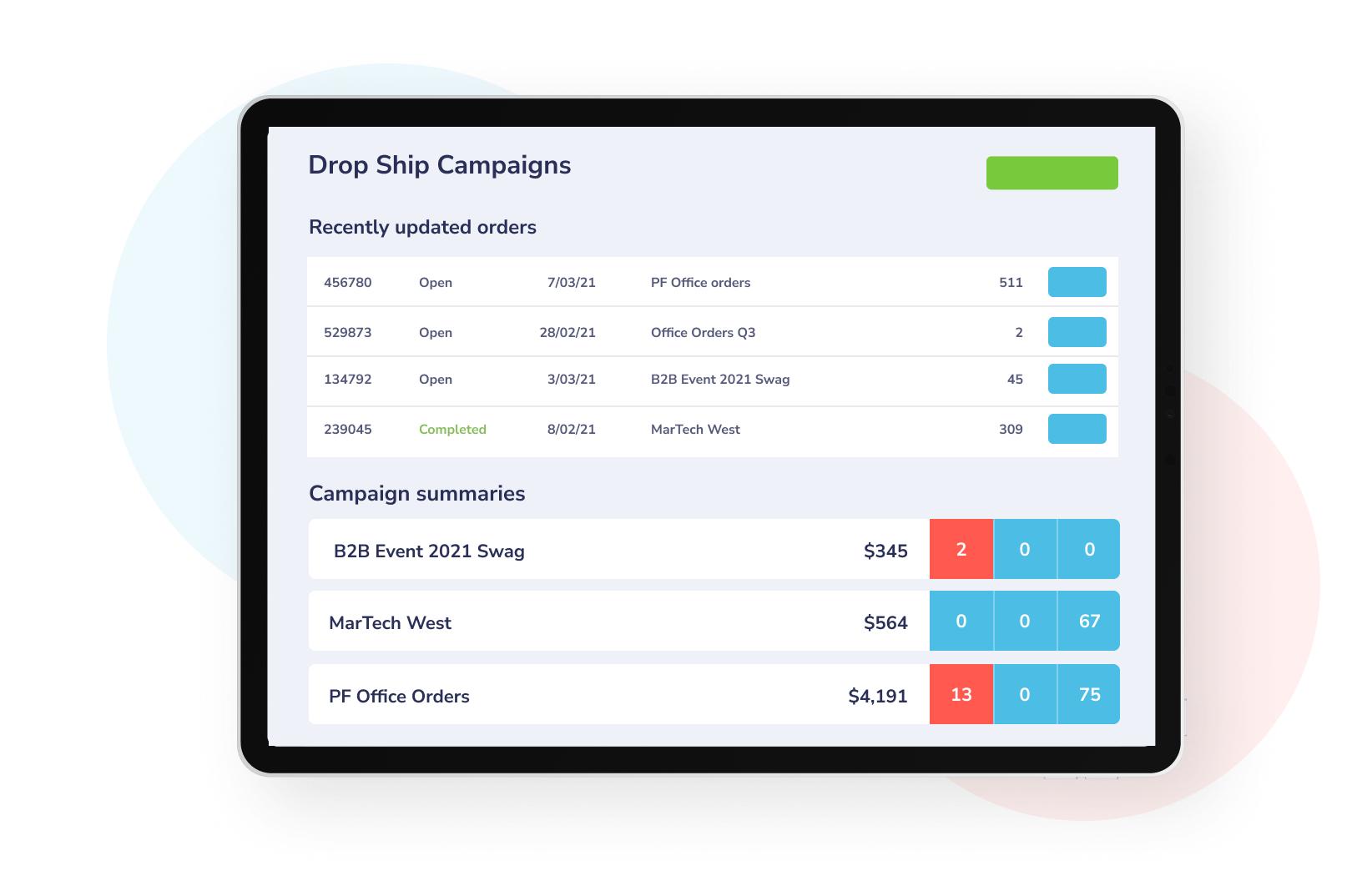

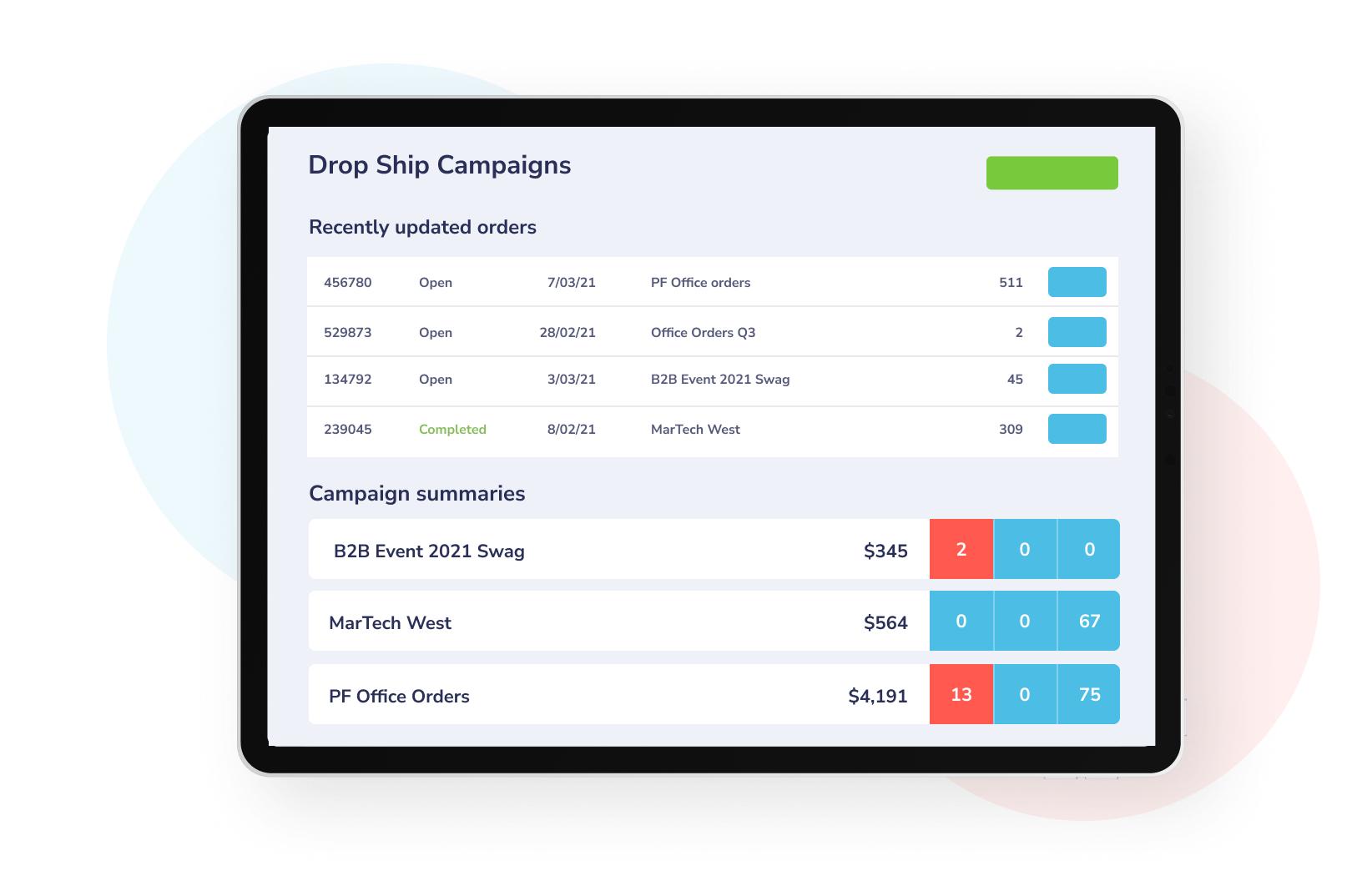

Drop ship swag anywhere with a click

- Get your time back and save hours of time by not shipping swag yourself.

- With just a few clicks — your drop shipments are placed.

- Oh, did we mention? No more unorganized boxes of shirts. Get apparel neatly rolled & labeled by size and gender.

Drop ship swag anywhere with a click

Get your time back and save hours of time by not shipping swag yourself.

With just a few clicks — your drop shipments are placed.

Oh did we mentioned it? No more unorganized boxes of shirts.

Get apparel neatly rolled & labeled by size.

More benefits of Printfection's drop shipping

Ship anything you can think of

- Mugs, t-shirts, hoodies, bottles, giant Jenga sets.

- You name it — we can ship it.

- Your items can even arrive on a specific date.

- Deliver to trade shows, your HQ, sales rep's home office, etc.

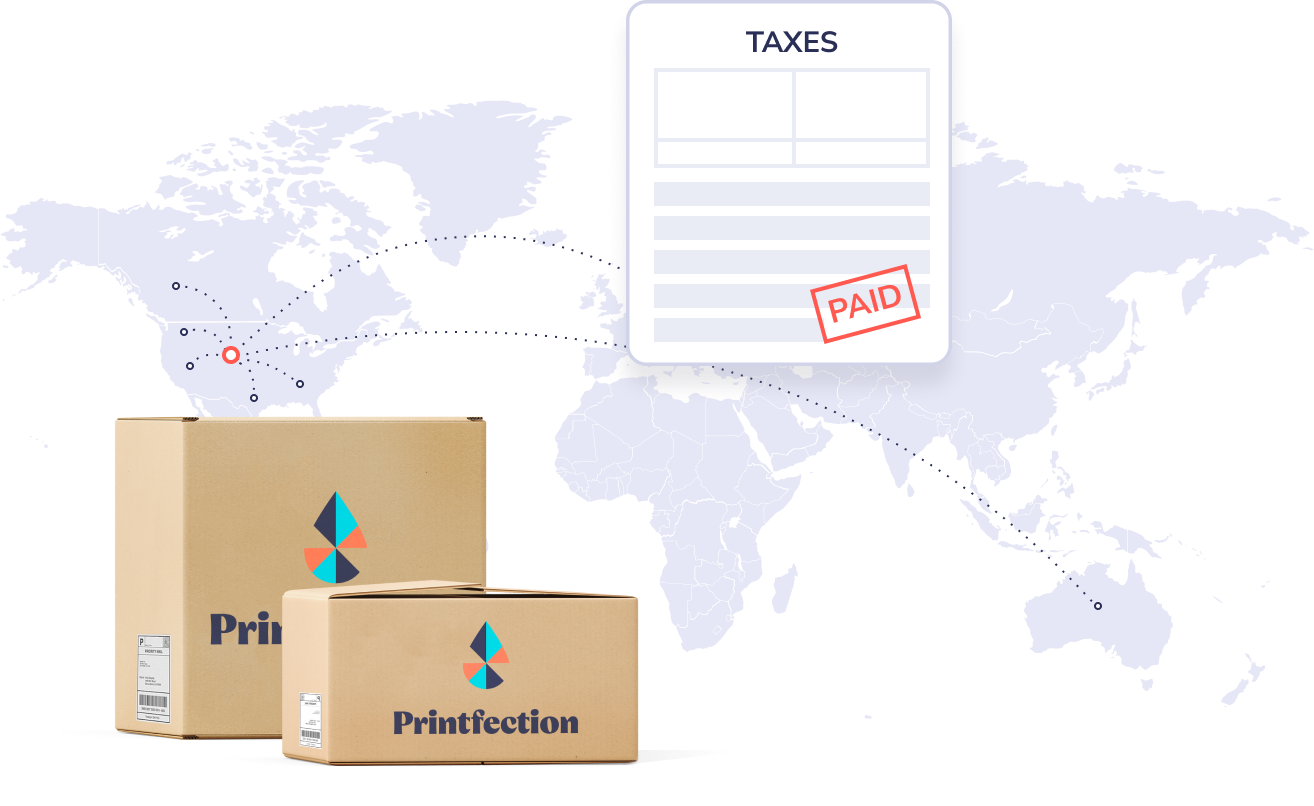

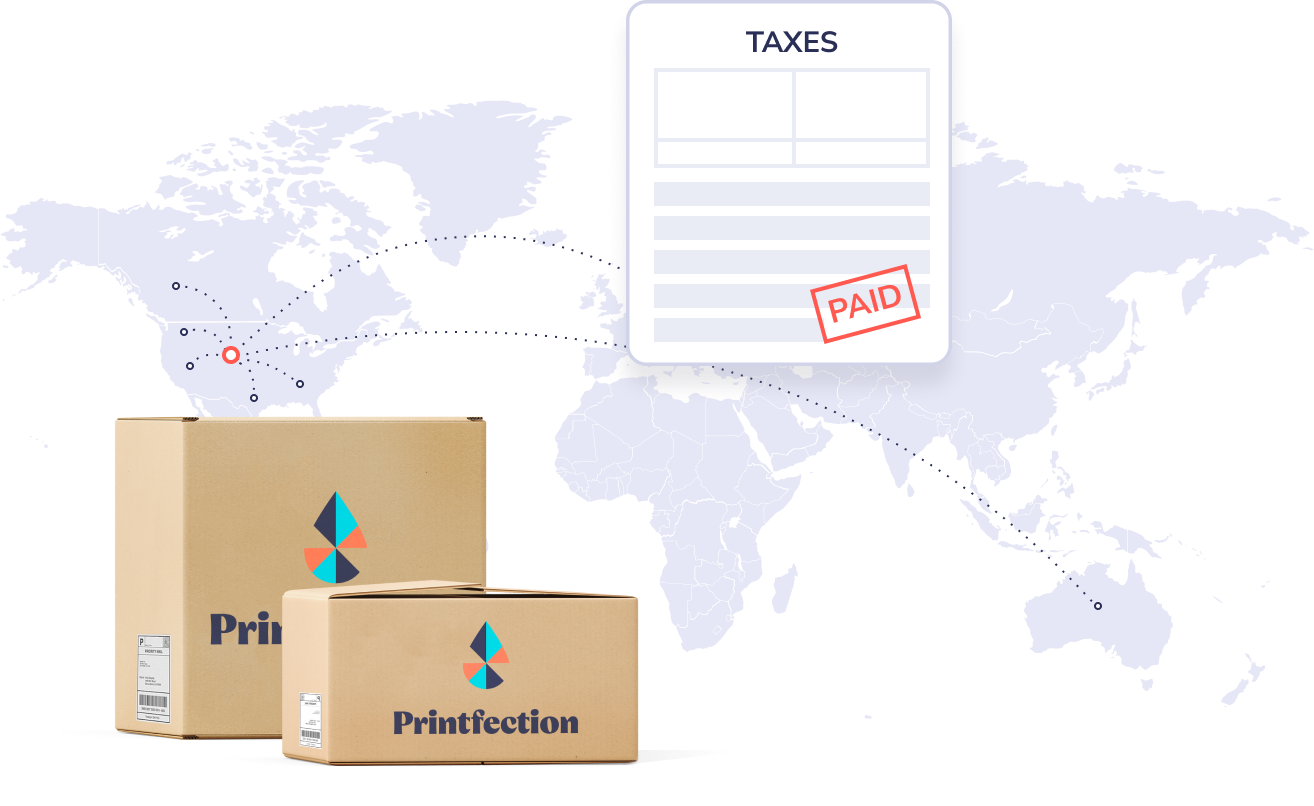

Worry-free international shipping

- Ship swag to over 200 countries worldwide.

- Taxes, customs fees, forms - we'll handle it!

- Getting swag to events overseas is a breeze.

- Stay up-to-date with package tracking & operations support.

More benefits of Printfection's drop shipping

Ship anything you can think of

- Mugs, t-shirts, hoodies, bottles, giant Jenga sets.

- You name it — we can ship it.

- Your items can even arrive on a specific date.

- Deliver to trade shows, your HQ, sales rep's home office, etc.

Worry-free international shipping

- Ship swag to over 200 countries worldwide.

- Taxes, customs fees, forms - we'll handle it!

- Getting swag to events overseas is a breeze.

- Stay up-to-date with package tracking & operations support.

More benefits of Printfection's drop shipping

Ship anything you can think of.

- Mugs, t-shirts, hoodies, bottles, giant Jenga sets.

- You name it — we can ship it.

- Your items can even arrive on a specific date.

- Deliver to trade shows, your HQ, sales rep's home office, etc.

Worry-free international shipping

- Ship swag to over 200 countries worldwide.

- Taxes, customs fees, forms - we'll handle it!

- Getting swag to events overseas is a breeze.

- Stay up-to-date with package tracking & operations support.

Dropship custom t-shirts too!

Easily design custom branded company shirts

Just send us your logo & artwork and we do the rest

Give away shirts to your fans, customers, and employees.

Dropship custom t-shirts too!

Easily design custom branded company shirts

Just send us your logo & artwork and we do the rest

Give away shirts to your fans, customers, and employees.

Dropship custom t-shirts too!

Easily design custom branded company shirts

Just send us your logo & artwork and we do the rest

Give away shirts to your fans, customers, and employees.

Ready to get started?

Our platform makes the sourcing, management, and distribution

of swag incredibly easy.

Ready to get started?

Our platform makes the sourcing, management, and distribution

of swag incredibly easy.